Construction Take-Off Services A Complete Guide

Construction take off services – Construction take-off services are crucial for any successful project. They provide a detailed breakdown of materials and costs, impacting everything from planning to bidding. This guide covers everything from defining different types of take-offs to utilizing software and data sources for accurate estimations. We’ll also explore the methods, techniques, and software used in this essential aspect of construction.

From initial planning to final bidding, take-off services play a critical role. They help project managers accurately estimate costs, enabling informed decisions at every stage. We’ll also discuss the importance of accurate data input and the potential pitfalls of inaccurate information.

Introduction to Construction Take-Off Services: Construction Take-Off Services

Construction take-off services are essential for any construction project. They’re like a detailed inventory of all the materials and labor needed to complete a building or infrastructure project. This process, from initial estimations to final cost breakdowns, ensures projects stay on budget and schedule. Accurate take-offs are critical for the planning, design, and bidding stages, preventing costly surprises down the road.

These services go beyond simply counting materials. They involve meticulous analysis, detailed measurements, and an understanding of project specifications. This allows for precise calculations of quantities required, ensuring a project’s financial viability. Different types of take-off services are tailored to specific project needs, providing a flexible and efficient solution for every stage of construction.

Types of Take-Off Services

Various types of take-off services cater to different project phases. Preliminary take-offs are used for initial feasibility studies, offering rough estimates. Detailed take-offs, on the other hand, provide precise quantity estimations for design and bidding. Each type plays a crucial role in the project lifecycle, ensuring the project stays within budget and scope.

Role of Take-Off Services in the Construction Project Lifecycle

Take-off services are integral to every stage of a construction project. They act as the financial compass, guiding project managers through cost estimations and accurate material calculations. This crucial step enables informed decisions at every stage, from early planning to completion.

Key Project Stages Requiring Take-Off Services

The table below articulates the vital role of take-off services at different project stages. Accurate estimations are essential for effective planning, design, and bidding.

| Project Stage | Take-Off Service Role | Example Task |

|---|---|---|

| Planning | Estimating initial costs | Preliminary take-off for feasibility study, identifying potential material costs |

| Design | Refining cost estimates | Detailed take-off for detailed design, incorporating precise specifications |

| Bidding | Accurate cost analysis for bids | Preparing cost breakdowns for contractors, ensuring accurate and competitive bids |

Methods and Techniques

Source: takeoffps.com

Construction take-off, the crucial initial step in project costing, relies on accurate estimations of materials and labor. Different methods are employed, each with its strengths and weaknesses. Understanding these methods and their impact on project timelines and accuracy is vital for effective project management.

Various methods exist for creating accurate construction take-offs. From simple manual calculations to sophisticated software applications, the right choice can significantly influence the project’s success. Each method brings its own set of advantages and disadvantages, directly affecting the time required for the task and the reliability of the final cost estimate.

Manual Take-Off Methods

Manual take-off methods, traditionally used, involve meticulous measurement and calculation of materials and labor. This often entails detailed drawings, site visits, and extensive manual calculations. While seemingly straightforward, manual methods can lead to significant errors due to human input. These errors can range from simple transcription mistakes to misinterpretations of complex drawings, leading to costly oversights in project budgeting.

Software-Based Take-Off Methods

Software-based take-off methods have revolutionized the industry. These programs use pre-loaded material specifications and automatically calculate quantities based on project plans. This process significantly reduces the chance of human error and speeds up the estimation process. Modern software also allows for the creation of detailed reports and cost breakdowns, making them valuable tools for project planning and control.

Comparison of Manual and Software-Based Methods

| Method | Advantages | Disadvantages | Accuracy |

|---|---|---|---|

| Manual | Low initial investment; potentially adaptable to specific project needs. | Prone to errors, time-consuming, particularly for complex projects, and relies heavily on the expertise and accuracy of the individual performing the calculations. | Medium |

| Software-based | High accuracy, speed, reduced human error, and detailed reporting capabilities. Can handle large and complex projects efficiently. | Requires software license, learning curve for operators, and potential for errors if data input is incorrect or the software is not correctly calibrated. | High |

Impact on Project Timelines

The chosen take-off method significantly affects project timelines. Manual take-offs are inherently time-consuming, particularly for large projects. Conversely, software-based methods can dramatically shorten the take-off phase, allowing project managers to move to the next stages more quickly. For instance, a large commercial building project could take weeks using manual methods, but software could complete the same task in days.

Accuracy Levels

Accuracy is critical in construction take-offs. Manual methods are susceptible to errors in measurement and calculation, leading to potential cost overruns or underestimations. Software-based methods, on the other hand, leverage algorithms and databases to minimize these errors, resulting in more accurate estimates. Real-world examples demonstrate the impact of accurate take-offs on project outcomes. A precise estimate prevents surprises and helps ensure projects stay within budget and on schedule.

Software and Tools

Source: digitalestimating.com

Construction take-off is significantly enhanced by the right software. Choosing the right tool can save time, reduce errors, and improve overall project efficiency. These tools provide a structured approach to gathering and analyzing data, making the entire process more organized and less prone to mistakes.

Popular Software for Construction Take-Off

Several software packages cater to construction take-off needs, offering varying levels of functionality and complexity. The selection of software depends on the project scale, the level of detail required, and the team’s familiarity with the chosen platform. Choosing software with intuitive interfaces and strong data management capabilities is crucial for efficient use.

Key Features of Construction Take-Off Software

Software packages for construction take-off offer a range of features. These features streamline the process by automating repetitive tasks, facilitating collaboration, and enhancing data accuracy. These tools improve the quality of take-offs and reduce the likelihood of costly errors.

- Data Input and Management: Sophisticated software often allows for importing and managing various data types, including material specifications, quantities, and pricing. This streamlined data management ensures consistency and accuracy throughout the process. Import functions for various formats, like spreadsheets, are common, simplifying the process of gathering information from different sources.

- Material Take-Off: Modern software automates the calculation of material quantities needed for a project. This feature often includes detailed breakdowns of different materials, simplifying the estimation process and reducing the chance of overlooking essential components. The software can also automatically calculate quantities based on project drawings, plans, or other data sources.

- Cost Estimation: Many software packages integrate cost estimation features, providing real-time updates based on current market prices. These tools help project managers accurately assess the project’s budget and identify potential cost overruns. This feature is invaluable for accurate budgeting and cost control.

- Collaboration and Communication: Cloud-based software often facilitates real-time collaboration among project teams. This allows for seamless communication and information sharing, especially on large-scale projects with multiple stakeholders. The ability to share and comment on drawings or documents improves team efficiency and reduces delays.

- Reporting and Analysis: Advanced software offers robust reporting and analysis capabilities. These tools enable project managers to track progress, identify potential issues, and make data-driven decisions. These reports can be customized to specific project needs, providing tailored insights.

Importance of Data Input Accuracy

Accurate data input is paramount in construction take-off software. Inaccurate data directly translates into flawed estimates, leading to potential budget overruns and project delays. This highlights the critical need for careful data entry and verification. A dedicated team and strict protocols for data entry can drastically reduce the risk of errors. Software should include features to validate input, preventing common mistakes like incorrect unit measurements or missing specifications.

Software Comparison Table

This table provides a concise overview of popular construction take-off software and their key features. Choosing the right software depends on the specific needs and requirements of the project.

| Software | Key Features | Accuracy | Example Use Case |

|---|---|---|---|

| Software A (Example) | Cloud-based, real-time collaboration, extensive material libraries, automated calculations, detailed reporting | High | Large-scale commercial projects requiring seamless collaboration and comprehensive data analysis |

| Software B (Example) | Detailed material take-off and cost estimation, advanced cost modeling, customizable reports, user-friendly interface | High | Residential construction projects needing precise material calculations and cost estimations |

| Software C (Example) | BIM integration, automated quantity surveying, comprehensive material database, advanced reporting | High | Complex infrastructure projects requiring precise quantity surveying and BIM integration |

Data Sources and Input

Construction take-off relies heavily on accurate data, and the quality of your final estimates depends on the quality of your input. Understanding the various data sources and their importance is crucial for a successful take-off. This section dives into the different data types, how to gather them effectively, and common pitfalls to avoid.

Different Data Sources

Various sources provide the information needed for construction take-off. These sources range from readily available blueprints to more detailed specifications. The more complete and accurate the data, the more reliable the take-off.

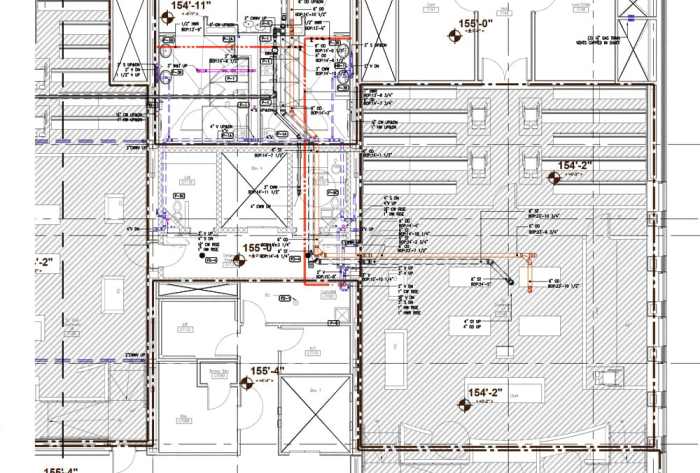

- Blueprints and Drawings: These visual documents are fundamental for accurate measurements. They show the layout, dimensions, and overall design of the project. Accurate scaling and careful measurement from blueprints are essential. Architectural plans, structural drawings, and site plans are all valuable sources.

- Specifications: Specifications provide detailed descriptions of materials, finishes, and quantities. They often list the exact type, grade, and required amount of each item. This is crucial for precise material estimations.

- Quantity Surveys: Pre-existing quantity surveys, if available, can be invaluable. They may contain already calculated quantities for specific elements of the project, which can be cross-referenced and validated against your data.

- Existing Site Data: Information about the existing site conditions is critical for the take-off. This includes details about existing utilities, topography, and potential obstacles.

- Material Price Lists: Gathering up-to-date material pricing is vital for accurate cost estimations. This can be from suppliers, industry publications, or online resources. Pricing is frequently subject to change.

Importance of Accurate Data Input

Inaccurate data input can lead to significant errors in your take-off. These errors can result in cost overruns, delays, and ultimately, project failure. Carefully collected and verified data is essential for reliable take-off results.

Procedures for Collecting and Verifying Data

A structured approach to data collection and verification is essential.

- Verification of Drawings: Double-check the accuracy of dimensions and quantities from blueprints. Use multiple sources for verification if possible. This can include checking measurements against various drawings, consulting with site engineers, or referencing past projects.

- Review of Specifications: Carefully review all relevant specifications for detailed material information. Ensure all details are understood and correctly interpreted.

- Data Validation: Compare data from various sources to ensure consistency and accuracy. Look for discrepancies or inconsistencies in data from different sources and investigate the root cause. This process can be automated or manual.

- Field Verification: If possible, physically verify data on site. This could include measuring actual dimensions or confirming material types. Field visits are particularly important for large or complex projects.

Examples of Errors and Mitigation

Common errors include misreading drawings, using outdated pricing data, and incorrect material quantities.

- Misreading Drawings: Incorrect measurements from blueprints can significantly impact the take-off. Use precision tools and double-check measurements. Have a colleague verify the measurements to avoid errors.

- Outdated Pricing: Use up-to-date pricing data to avoid significant cost inaccuracies. Consult with material suppliers or use online resources for the most current pricing information.

- Incorrect Material Quantities: Ensure you’ve accounted for all material types and quantities specified in the project documents. Use a detailed checklist to verify all items.

Data Source Table

The table below illustrates the different data sources and their relevance in take-off.

| Data Source | Type | Relevance in Take-off | Example |

|---|---|---|---|

| Blueprints | Visual | Essential for accurate measurements and project layout | Architectural plans, structural drawings |

| Specifications | Textual | Provides detailed material information and quantities | Material lists, finish schedules |

| Quantity Surveys (if available) | Calculated | Significantly speed up the take-off process | Existing quantities for similar projects |

| Site Data | Physical | Critical for understanding existing conditions and potential obstacles | Utilities, topography, existing structures |

| Material Price Lists | Financial | Essential for accurate cost estimation | Supplier catalogs, online pricing |

Cost Estimation and Analysis

Source: amazonaws.com

Estimating the total cost of a construction project is crucial for project success. Accurate cost estimations are vital for budgeting, scheduling, and, ultimately, profitability. This process involves calculating material costs, labor costs, and various other project expenses, and factoring in contingencies. A well-defined cost analysis procedure ensures that the project stays within budget and meets profitability goals.

Material Cost Calculation Methods

Material costs are a significant portion of any construction project. Accurate calculation is essential to avoid cost overruns. Methods for determining material costs include:

- Unit Pricing: This method involves multiplying the unit cost of a material by the total quantity required. For instance, if a project needs 100 cubic meters of concrete at $150 per cubic meter, the total cost is $15,000. This straightforward approach is commonly used for standardized materials.

- Quotation-Based Pricing: This method involves obtaining quotations from suppliers or vendors. This approach is beneficial when dealing with customized materials or complex projects where precise quantities are difficult to determine beforehand. Analyzing quotes from multiple vendors allows for a more comprehensive comparison and selection of the most competitive pricing.

- Cost Per Unit Area or Volume: Useful for calculating costs associated with materials applied over a specific area or volume, like roofing materials or flooring. This method simplifies the calculation by considering the area or volume as a whole.

Labor Cost Estimation

Labor costs are a substantial part of construction projects. Accurate estimation is essential to manage project budgets effectively. Methods for estimating labor costs include:

- Labor Rate Analysis: This involves researching prevailing wage rates for specific trades and tasks within the project location. It considers factors such as experience levels, skill sets, and local regulations. This process often involves consulting industry resources or local labor boards.

- Task Duration Estimation: Estimating the time required for each labor task is critical. Detailed task breakdown and experience-based time estimations are essential. This method involves carefully planning each step of the project and considering potential delays or complications.

- Labor Productivity Factors: Construction projects often have variable labor productivity due to factors like weather conditions, site access, and equipment availability. Incorporating these factors into the labor cost calculation is important to accurately reflect the project’s potential challenges.

Other Project Expenses

Other project expenses include site preparation, permits, equipment rental, insurance, and professional fees.

- Detailed Breakdown: A detailed breakdown of all anticipated expenses, categorized for clarity, is crucial. This often involves consulting with project managers, architects, and other stakeholders.

- Contingency Planning: A contingency plan should be included to address unforeseen circumstances. This involves setting aside a percentage of the budget to cover potential cost increases or unexpected issues.

Contingency Planning Significance

Contingency planning is crucial in construction take-offs to account for unforeseen circumstances. A well-defined contingency plan minimizes project delays and cost overruns.

Contingency planning involves setting aside a percentage of the budget to account for potential cost increases or unexpected issues.

The percentage varies based on project complexity, location, and market conditions. A common contingency amount is 5-10% of the total project cost.

Cost Analysis Procedure

- Gather Data: Collect all relevant information, including material costs, labor rates, and project specifications.

- Calculate Material Costs: Employ the appropriate methods to determine the precise cost of all materials required for the project.

- Estimate Labor Costs: Accurately estimate labor costs based on task duration, labor rates, and productivity factors.

- Determine Other Expenses: Include all additional expenses such as site preparation, permits, equipment rentals, insurance, and professional fees.

- Establish a Contingency Fund: Allocate a portion of the budget for unforeseen circumstances, such as price fluctuations or delays.

- Analyze and Review: Thoroughly review the cost analysis to ensure accuracy and completeness.

Cost Factors Table, Construction take off services

| Cost Factor | Description | Impact on Take-Off | Example |

|---|---|---|---|

| Material Cost | Cost of raw materials | Directly affects overall project budget | Steel, concrete, lumber |

| Labor Cost | Cost of labor for construction tasks | Significant component of the total cost | Carpenter, electrician, plumber |

| Equipment Cost | Rental or purchase cost of construction equipment | Impacts the project budget, especially for large-scale projects | Crane, bulldozer, excavator |

| Site Preparation | Cost of site preparation and clearing | Can vary greatly depending on the site conditions | Clearing land, grading, and excavation |

| Permits and Licenses | Cost of necessary permits and licenses | Dependent on local regulations | Building permits, zoning permits |

| Contingency | Allowance for unexpected costs | Protects against cost overruns | 5-10% of total project cost |

Closing Notes

In conclusion, construction take-off services are indispensable tools for navigating the complexities of project planning and execution. Understanding the various methods, software, and data sources is vital for precise cost estimations. By meticulously gathering and analyzing data, project managers can make well-informed decisions and ensure the financial success of their ventures. This process allows for better control over budgets, timelines, and ultimately, project outcomes.